Warehouse optimization is an essential part of effective supply chain management. How well the warehouse is optimized depends on the speed and accuracy of goods delivery, affecting clients’ experience, thus — business income.

Some entrepreneurs think of optimization as applying autonomous robotics, while others decide to start with digital solutions implementation. Though, the truth is in the middle. Keep reading this post to know how to optimize your warehouse to make the most out of it.

Essence of Warehouse Optimization

Behind the warehouse optimization lies automating processes aiming to increase efficiency by increasing visibility of all the activities happening within the warehouse. In addition, optimizing a storehouse means making such an environment in which high-demand stocks are always supplied, evoking timely order filling.

A great deal of a retail businesss’s success depends on the ability to make effective supply chain loops and cut expenses. It can be possible due to automated warehouse systems addressing the most vital storehouse operations. When many processes are digitized, it creates a background for better inventory flow, faster picking and receiving procedures, and control over the equipment.

Innovative Technologies for Warehouse Optimization

There are different technologies that can be applied to optimize warehouse-related operations. I’ve rounded up five of the most widespread ones that may assist you in managing efficiency during the entire order lifecycle.

Barcodes

Barcode systems are an indispensable part of warehouse optimization. How does the technology work? First, scanners apply cameras to read the barcode stripes. Then the record inventory’ data is transferred to the warehouse management system for further processing. One of the advantages of some systems is the ability to get real-time information, thus speeding up the item tracking process. They’re made to ensure accurate inventory registration in the accounting system. Knowing the exact stock availability level helps executives make data-driven decisions rather than assumptions.

RFID Tags

RFID tags are also applied to trace warehouse inventory, increasing visibility. Unlike barcodes that demand proximity to the items, RFID technology employs antennas linked to a microchip enabling the data recording from a distance. There are active and passive RFID tags. Active tags are installed throughout the warehouse, and information is transmitted through electromagnetic waves. In turn, passive tags need specialized devices to be launched.

GPS Systems

GPS-powered solutions are mainly used to navigate the storehouse and monitor inventory conditions. This enables prompt failure detection and finding the needed stocks. Geolocation systems can also streamline load planning and multi-driver routes in the most cost-effective way. For example, using GPS technology during the last mile improves clients’ experience, enabling them to trace the good’s position in transit.

Voice Technology

Such technologies contribute to faster package picking operations fulfillment. Workers are guided by a tasker using wireless headsets with a microphone. The operators obtain instructions from smartphones or tablets to know which picking task needs to be carried out and where.

Cloud Storage

The logistics industry deals with tons of information that must be stored and organized. Cloud software development is a proven approach to handling vast data due to solution scalability. You can quickly expand your storage on demand while reducing inner infrastructure costs.

Autonomous Robotics

Implementing autonomous robotics (e.g., aerial vehicles, drones, sortation systems, robots) leads to accelerated warehouse-related processes. They strive to simplify labor-intensive work leaving stock management to managers. Their core task is to effectively move items around the warehouse and ensure everything has its place. For example, drones can perform inventory counting and inform workers about the inventory that needs to be relocated or/and restocked.

Software Solution for Warehouse Optimization

No matter how sophisticated the technology is, you need a robust software background to supervise it.

Warehouse management system (WMS)

WMS focuses on supervising the whole storehouse, including resource tracking, order tracing optimization, and load planning. Such a system is designed to optimize the commodities allocation, control picking and packing methods, generate invoices, transmit push notifications, and more.

Inventory management software (IMS)

IMS has a narrow spectrum of responsibilities and is restricted to stock control during the entire product lifecycle: from acquiring raw materials to shipping finished goods and last-mile delivery. For example, the system can be applied to streamline and scale your storage space and release space for new orders.

Mobile-based solutions for warehouse associates

Logistics managers require mobile applications to take reins over the supplies and commodities, manage/upgrade the stock prices, analyze order records, view statistical reports, and more.

Additionally, your warehouse management software needs to centralize with existing утеукзкшіу systems, such as ERP software, HR management software, logistics management systems, etc. In case you plan to outsource some supply chain management activities (e.g., freight management), you should consider shipping APIs integration. It’s a group of tools that make it possible to connect with logistics service suppliers.

How To Build Warehouse Management App

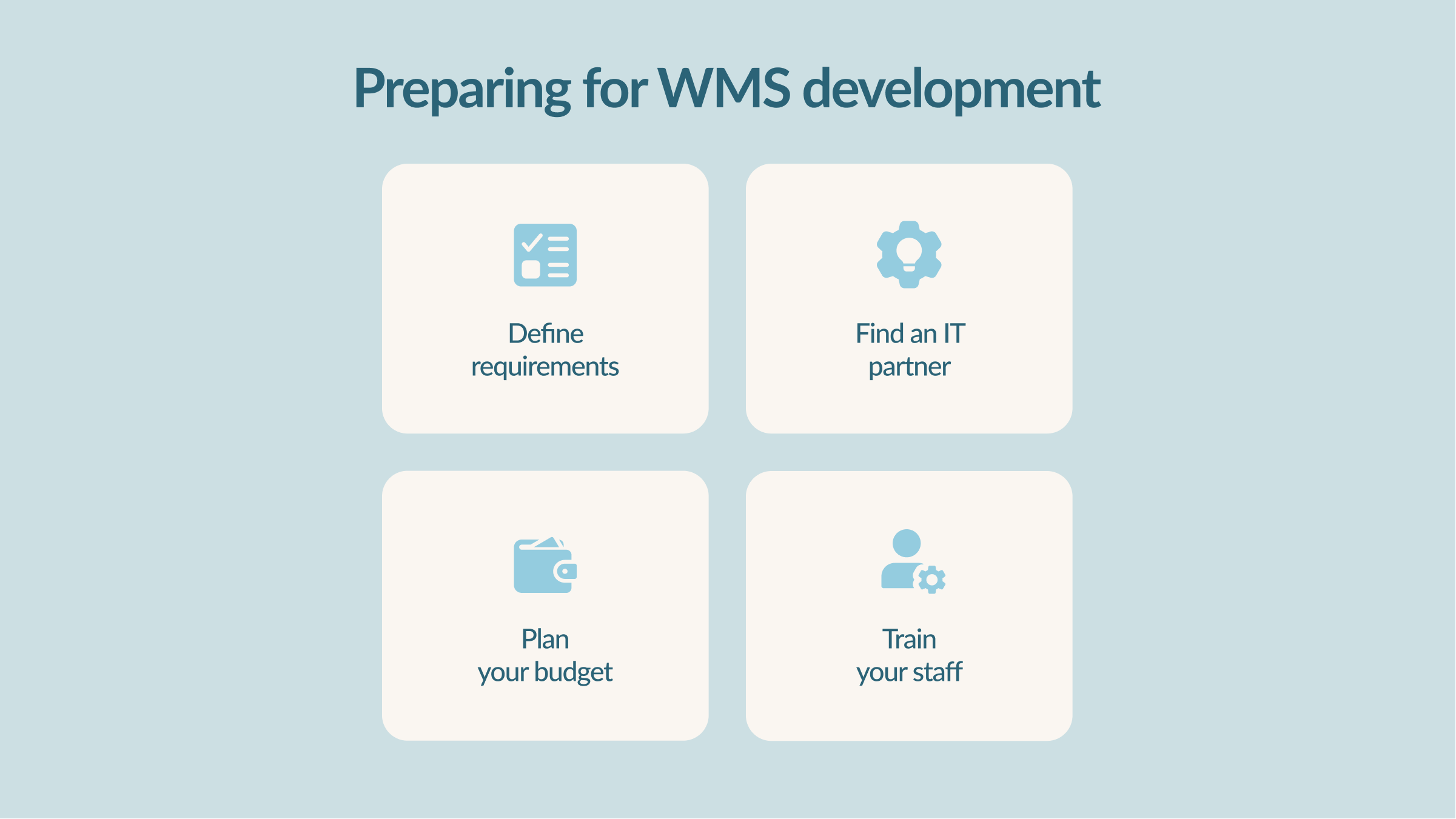

Set up business requirements

Any warehouse management app is designed to address specific storehouse-related needs. Therefore, you must define your ongoing challenges that should be solved by initiating a custom logistics solution. For example, you may want to improve asset control or streamline storage space.

Hire an IT provider

Deciding on an app concept and defining a project’s demands is a part of the journey. You need experts who will turn your vision into a reliable and secure system. When looking for a tech implementer, ensure they have proven industry expertise. This way, you’ll assure you get the desired product.

Plan budget

Before embarking on app development, you need to properly plan the budget. The main costs will be the payment of an expert team engaged in the implementation process. Outsourcing project development is an excellent way to cut expenses without sacrificing product quality. This model is known for its profitability and broad expertise availability. Even though IT consulting prices vary depending on region, you can look for professionals globally meeting your budget and requirements needs.

Personel onboarding

Introducing new technology is associated with team adaptation challenges. Therefore, it’s essential to account for effective onboarding practices to ensure your employees are prepared to work with newly integrated tools and programs.

Final Thoughts

The question of digitizing the warehouse processes is always hard. On the one hand, you need to invest a pretty penny in the development, teach your in-house employees, and, in some cases, redesign your storehouse to adapt it to new technological solutions. On the other hand, introducing new software solutions backed with innovations create added business value.